Every Machine Every Metric

One Intelligent System

MachineData.Ai connects, analyzes, and optimizes your entire production floor in real time — with AI that learns, predicts, and acts.

All-in-One Industrial IoT Platform for

Smart Manufacturing

Seamlessly monitor, automate, and optimize every aspect of your industrial operations with real-time intelligence.

Industrial Monitoring

Robust monitoring solutions designed for industrial IoT devices — delivering real-time performance alerts, fault diagnostics, and predictive insights to keep your operations running smoothly.

Manufacturing Analytics

Turn machine-level data into strategic decisions with advanced analytics, AI-powered trend detection, and customizable dashboards built for operational excellence.

Process Automation

Automate critical production workflows with intelligent scheduling, maintenance triggers, and adaptive process control to boost efficiency and reduce manual intervention.

One Platform. Multiple Agents.

All Insights

AI Weld Agent

- Wire Deposition Monitoring

- Gas Flow & Power Analytics

- 15% Less Energy Consumption

- Closed-loop Predictive Maintenance

AI Genset Agent

- Fuel & Coolant Monitoring

- Battery Management

- Alarm-Driven Fault Detection

- Auto-Scheduled Reports

AI Process Line Agent

- Component Output Monitoring

- Variable Temperature Tracking

- Downtime Reduction up to 97%

- Protocol-based Maintenance Calls

AI-Powered Agents for Smart Factories

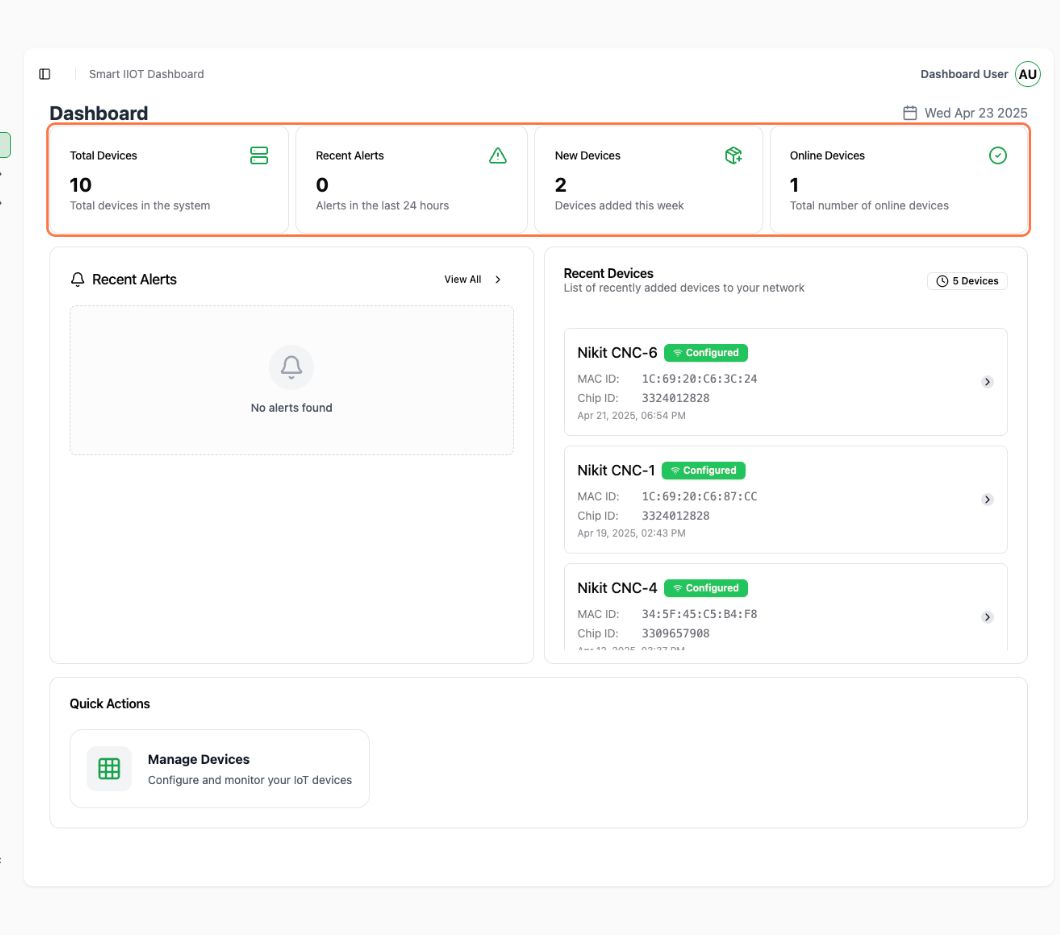

Real-Time Machine Monitoring

Monitor live machine data, status, and performance metrics from one unified, intelligent dashboard.

Predictive Maintenance

Detect faults early, reduce unplanned downtime, and increase machine life with AI-powered predictions.

Smart Energy Management

Track energy use across machines to cut idle loss and reduce electricity costs.

Shift & Productivity Analytics

Analyze production, shift output, & operator efficiency to optimize overall manufacturing.

Intelligent Alerts & Notifications

Get automated alerts for maintenance, quality checks, downtime events, and material loading instantly.

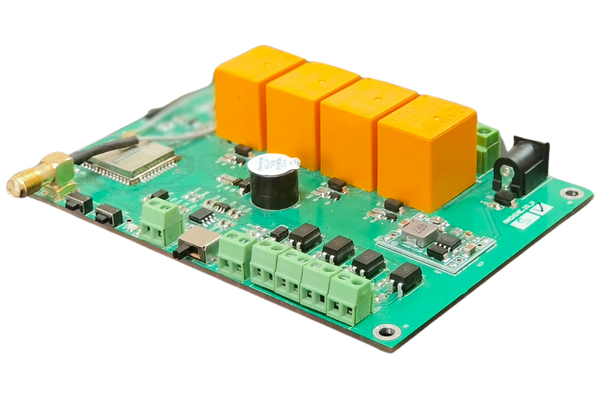

Cloud-Based & Edge-Ready

Access data anytime with secure cloud or edge deployment and offline syncing capabilities.

$470B Addressable Market

by 2030

From welding automation to predictive maintenance, MachineData.Ai taps into

$12T

Global Manufacturing TAM

Global manufacturing transformation drives demand for intelligent automation, data insights, and operational efficiency.

$470B

Predictive Maintenance Market

AI-powered maintenance solutions cut downtime and costs, capturing a massive industrial service opportunity.

$28B

Welding & Energy Opportunity (2024)

Smart welding, energy analytics, and automation tools unlock huge gains in industrial productivity and savings.

Ahead of the Competition

— By Design

We benchmarked against the best. Here’s why MachineData.Ai leads:

Proven in Production

Trusted by Industries

Real-world success stories showcasing how MachineData.Ai delivers measurable results across diverse industrial environments.

Smart Energy Optimization

Smart Energy Optimization Smart Energy Optimization Solutions – Across Industries...

KAPL Automotive

KAPL – Automotive Manufacturing KAPL Automotive – Unlocking Predictive Power...